Enter Text

Powerlift Dumbwaiter Installation

For Sales Call: 831-999-3399

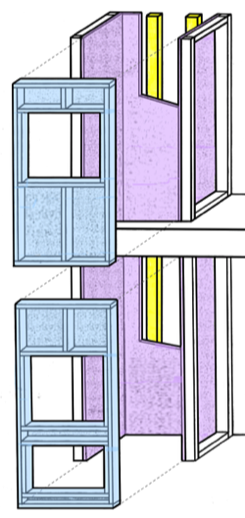

Preparing your Hoist-Way for Installation

Hoist-Way preparation details highlighted

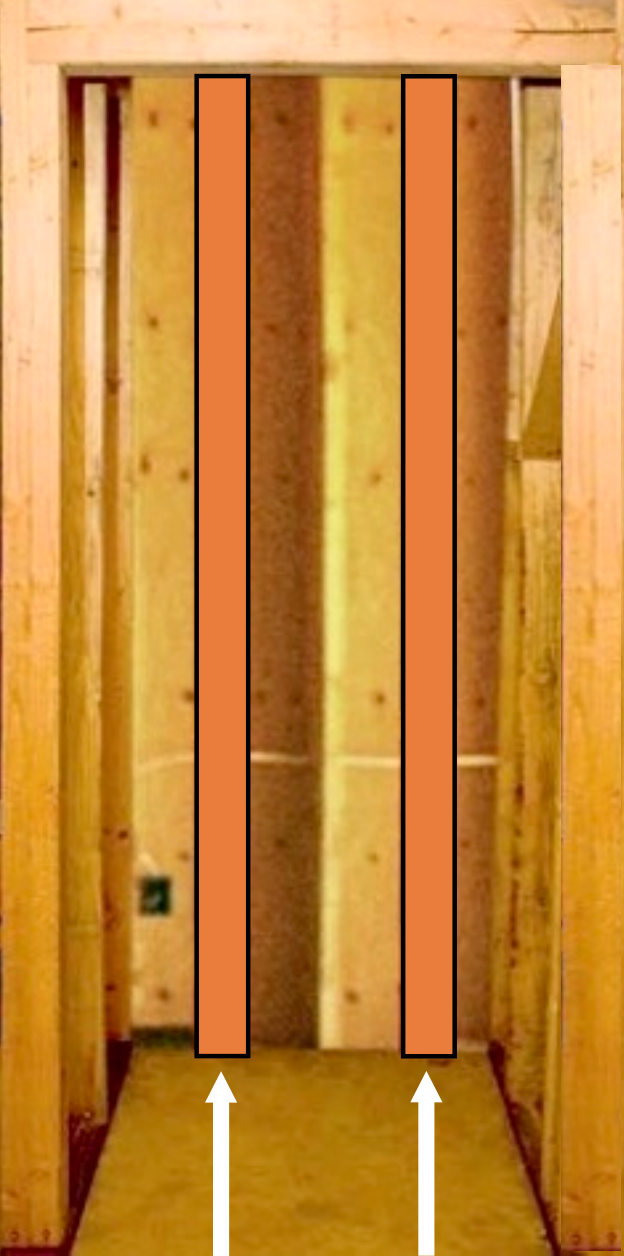

2x6 Vertical Backing

The Powerlift Dumbwaiter requires an existing

Hoist-Way with a dedicated electrical circuit,

2x6 vertical backing for the track & rail assemblies

to bolt too, starting from the floor at the1st stop

to ceiling at the top stop.

Hoist-Way Door Openings

Leave the Hoist-Way door openings unframed from

floor to ceiling & full width until the Dumbwaiter

is installed and tested. This would include leaving

one wall open on any floor that the Dumbwaiter

passes threw without stoping. On any floor that

has multiple openings to the Hoist-Way only

one opening should be left unframed.

Hoist-Way Sheathing

Before sheathing the Hoist-Way ensure a dedicated circuit has been provided for the Dumbwaiter.

Sheetrock & tape inside framed portion of the Hoist-Way or with other code compliant sheathing.

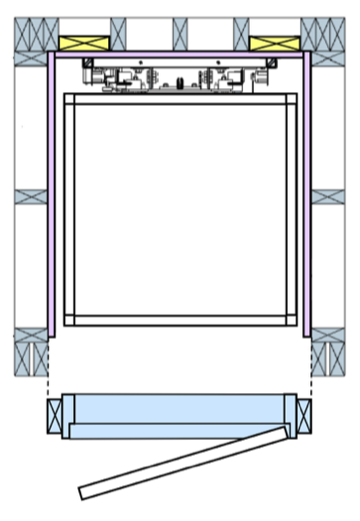

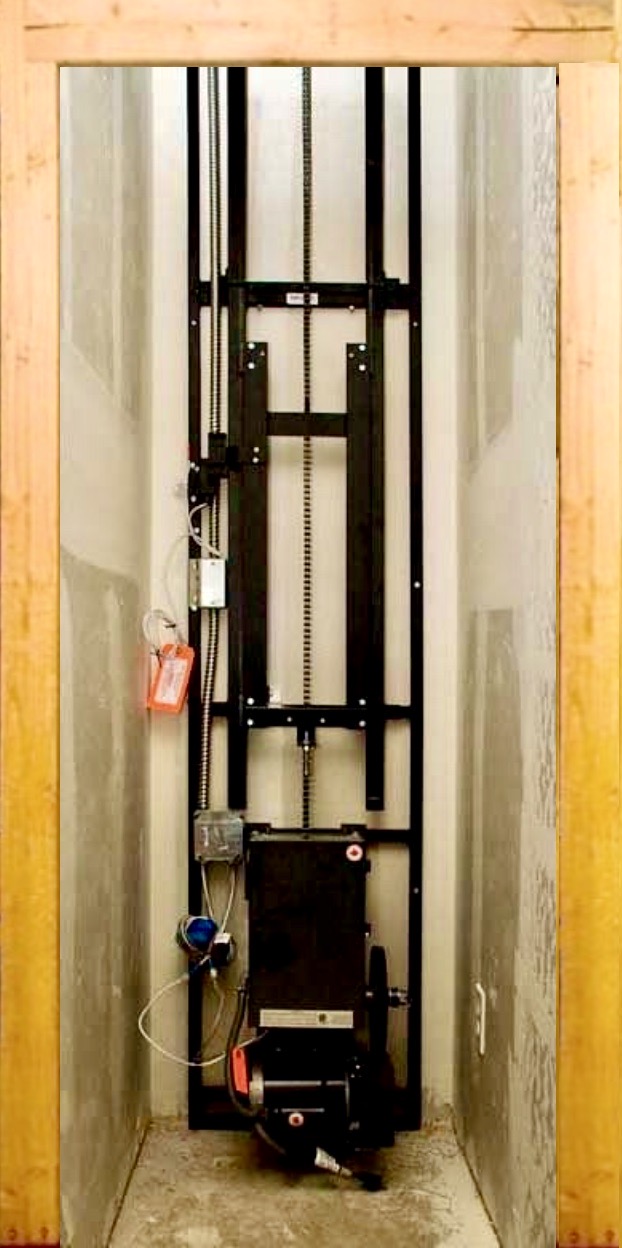

Powerlift's modular dumbwaiter design consists of pre-assembled components for easy installation as illustrated below:

Framed Hoist-Way with 2x6 vertical backing for track & rail assemblies. Hoist-Way door openings left unframed for installation purposes.

Sheetrocked & taped Hoist-Way with dedicated eletrical circuit. Check your local codes for sheathing & electrical requirements.

The motor, controller & chassis come assembled as one unit that bolt to the track & rail assembly before installing in to the Hoist-Way.

Track & rail assemblies come pre-assembled, stacked one on top of another, bolt together & fastened to the 2x6 vertical backing.

The track & rail assembly at the top have the low voltage wiring done for you in flex conduit with easy too plug in connections.

After the Hoist-Way door openings have been framed in, sheathed inside & out, doors installed & finished you can hook up the call & send stations, safity switches & innerlocks.